We are a Czech Production Company situated in North Czech Republic (Bohemia) in Chrastava, Liberec region. Our Company has been operating as Vzduchotechnik since 1992, but we were manufacturing various devices and equipment under the name "Liberecké Vzduchotechnické Závody" (LVZ) since 1950.

We have a long tradition in the production and installation of a wide range of industrial air ventilation equipment, which has helped to maintain a clean and healthy environment and also keep a pleasant climate in various workplaces, in the industrial factories, in offices, hotel rooms and sport halls.

Over the 60 years of manufacturing we have gained the knowledge to focus on highly efficient and reliable systems designated for air extraction and filtration for all types of industrial, military and civilian installations. Basic categories of our production range are:

- Industrial dust exhaustors with three mechanical filtration stages (cyclone separators, automatized units with bag or cartridge filters)

- Ventilation systems (pipeline and portable ventilators, roof ventilation units, pipeline mufflers and noise suppressors, heating units, shutters and other components of classic ventilation systems)

- Filtration units (filtration cartridges and filter housings, bag and sleeve filters, stripe filters, clean extensions and special filtration equipment)

- Electrostatic filters (advanced filtration technology using ionization and electrostatic separation of very fine elements and micro-particles)

Custom Production

We are a medium size company (100 – 130 employees) therefore we can be flexible enough to be able to manufacture custom and standard products or parts on-demand. A big part of our production is delivered as specially modified equipment or as appliances directly designed according to requests of our customers. That is why our catalog rather represents summary of the most frequently used modifications and standards but does not cover our technical limits in full range. Thanks to the wide variety of machinery equipment we are able to design and produce any utility item or construction made of all usual or common metals under very reasonable conditions. Full production range of our company has been certified according to the latest ISO 9001 standards.

Sheet metal processing and metalworking

SHEET METAL CUTTING - metal cutting shears (NC) for 6 mm maximum thickness, length of sheet metal cut maximum 3000 mm.

SHEET METAL PUNCHING - most up-to-date blanking press TruPunch 5000 (most advanced series Trumpf) with high accuracy and performance, processing sheet metal up to 6 mm thickness, maximum dimensions 1250x2500 mm.

SHEET METAL BENDING - we use three bending presses (CNC) for processing sheet metal up to 6 mm thickness and maximum 2500 mm length.

SHEET METAL WELDING - we use welding stations for TIG, MIG welding of steel, aluminium and stainless steel sheet metal.

SURFACE FINISHING - after three stage presurface preparation (blasting, degreasing and possible phosphatizing) we can provide surface finishing by powder coating or by spraying.

Advanced industrial dust exhausters are the basic pillar of our production. Filtered and clean air can be returned back to the interior, which especially in the winter months could significantly reduce costs of heating for workshops and factory buildings. We are able to provide equipment for all known classes of filtration from gross mechanical separators and cyclone separators, pneumatically regenerated bag, sleeve and cartridge filters to fine electrostatic filter units and HEPA filters installed to clean rooms. Our special production covers even the production of filtration equipment for dangerous areas with a high risk of explosions and for other non-standard environments.

Datasheets and industrial standards:

Dust exhaustors POC 14/20/30 - modular design (size 14/20/30, bag filters, 1400-3000 m³/hour) POC-14-20-30.pdf

Industrial dust exhaustors POC - OM 6/9 (600/900 m³/hour)

Cartridge dust exhaustor POC 6/9 (air extraction arm, handles and carrier, prefilter)

Cartridge dust exhaustor POC - OM 6/9 (for extraction of oil fog, 600/900 m³/hour)

Cartridge air exhaustors series POC 20/30/40/60 - JET (with an automatic pneumatic cleaning of the filter cartridge, 2000-6000 m³/hour)

POC-20-30-JET.pdf POC-40-60-JET.pdf

Cartridge dust exhaustor POC 9 JET (with an automatic pneumatic cleaning of the filter cartridge, 950 m³/hour)

Industrial dust exhaustor FMV-6 (with six filter cartridges, 6000 m³/hour)

Industrial dust exhaustor FM-12/16/18 (with filter cartridges, 1200 - 18000 m³/hour)

FM-12.pdf FM-16.pdf

Water separator VO

LIWEX dust exhaustion units 9, 9/2, 12 for welding (900-1200 m³/hour) LIWEX.pdf

Cartridge dust exhaustor for welding JPO 1200 (1200 m³/hour)

Dust exhaustion arm D 150 or D 200 mm (accessories to LIWEX and POC dust exhaustion units and to LIVENT ventilators)

Cyclone filter D630, D450, D950 and D1230 (2000-14 000 m³/hour)

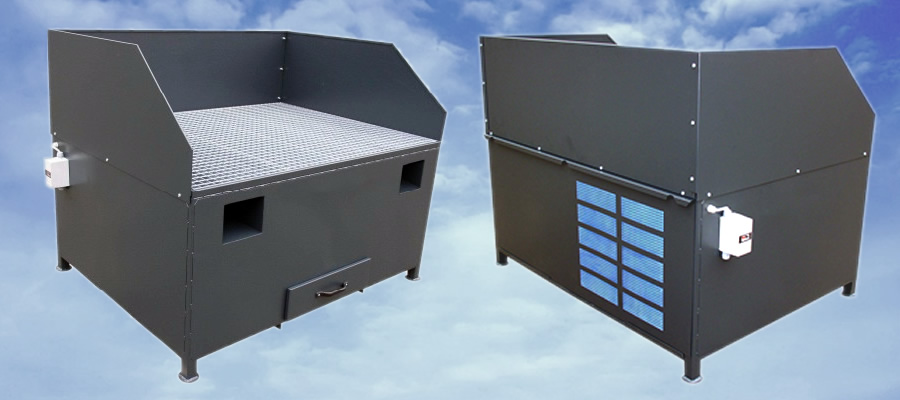

Table for welding WELDEK Covered table for welding WELBOX (with closed booth)

Table for grinding with ventilator BSPO Table for grinding BS (without ventilator)

Wide variety of ventilators, including independent power units and ventilator housings for industrial dust exhaustors, components of classic ventilation systems and roof mounted ventilation units of various diametres are within our production range. We are even able to offer ventilators with special antistatic finish to be used in hazardous areas with high risk of explosion.

Datasheets and industrial standards:

Air extraction ventilators LIVENT 4 and 12 (400-1200 m³/hour)

Portable and wall-mounted ventilators PV/ZV (800-4300 m³/hour)

Roof mounted ventilation units DVJ-450 (diagonal ventilators, 3000-4000 m³/hour)

Roof mounted ventilation units N-RVJ-C (radial ventilators, 1000-4000 m³/hour)

Roof mounted ventilation units NDA (diagonal ventilators, 7000-10000 m³/hour)

Accessories to DVJ and N-RVJ ventilation units (subpressure shutter, baseplate, mating flange, transition and roof extension, anchoring frame)

Roof mounted muffler chamber NTK (carryig element for CVJ and N-RVJ with efficient acoustic power muffler)

Filters and filtration units

Nearly all types of filtration units (replacement inserts, housings, high capacity panel filters with automatic regeneration, etc.) for wide use with all filtration stages from various dust separation to fine hepafilters for clean rooms and specific sorption filters for harmful chemicals are within traditional production range of our company. Sewing customized bag and sleeve filters, shaping all sorts of filtration materials and production of standardized and non-standardized filtration inserts for all kinds of pollutants are within standard services offered by our company.

Filtration elements and materials (general overview and classification into standard tiers and relevant fields of application)

Cell filters FVB and FVC (modular system of filtration housings, FVB with side insert extraction and FVC with front insert extraction)

Band filters FPC (stripe unwinding filters with manual or automatic feed, 25000-50000 m³/hour)

Cell filters FVS (1500 m³/hour for one chamber, modular design)

Filtration supplements:

Air filtration cells KOFIL (for trapping sparks from grinding/welding and separation of greasy vapours)

Air filtration cells KS (for first stage of filtartion on extraction piping from filtration booths)

Air filtration cells VBA (with polyester fabric for filtration of athmospheric air, EU2 level)

Air filtration cells VCK (with polyester fabric for filtration of athmospheric air, EU3 level, possibly with carbotex)

Air filtration cells VFT (with polyester fabric for filtration of athmospheric air, EU4, EU7 and EU9 levels)

Sorption filtration cells VS (with active carbon to capture harmful impurities and odours)

Air filtration cells FVK (bag inserts for use with air condition units, various levels of filtration, 1700/3400 m³/hour)

Air filtration cells VTA, VUA (filters based on synthetic respectively glass microfibers, levels E10, E11)

Absolute filters series WELFIL (for clean rooms, BIO filter for filtration levels F8, F9, E10 and E11 and HEPA filter for filtration levels H12 and H13)

Contact:

Bohumil Malý +420 488 881 063 +420 737 248 724 b.maly@vzduchotechnik.cz

Internet: www.vzduchotechnik.cz

Address: VZDUCHOTECHNIK s.r.o.

Tovarni ulice 548

Chrastava 463 31

Czech Republic

GPS : N50.81161 E14.958621

IČO : 40233707

DIČ: CZ40233707